N-TGD Steel Core Belt Conveyor

Equipment Accessories

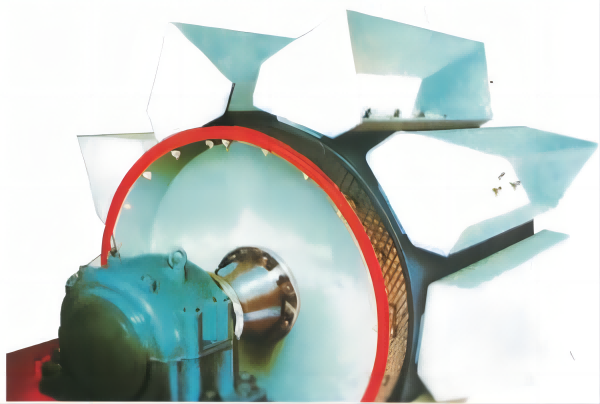

The N-TGD steel wire rope core belt bucket elevator uses high-strength special steel wire core tape as the traction component, which overcomes the dynamic load generated by the drive when the chain and sprocket mesh. Compared with the chain elevator, it works more smoothly and lighter, and can Faster running speed achieves higher productivity. Under the same production conditions, the tape can reduce the line load of the material and the line load of the traction components due to its high working speed and light weight, thus reducing the size of the entire machine. Self-respect. The use of high-strength steel wire rope core tape greatly improves the lifting height and conveying capacity of the elevator. The driving part is equipped with a slow-speed maintenance motor and is equipped with a backstop. The middle part adopts a double-channel structure, and the lower part adopts automatic tensioning. It is equipped with a specially structured tail roller to ensure automatic centering of the tape. The whole machine is equipped with safety protection devices such as deviation alarm, speed detection, and material level alarm to realize automatic monitoring of the status of the equipment during operation.

Details

Online Inquiry

The N-TGD steel wire rope core belt bucket elevator uses high-strength special steel wire core tape as the traction component, which overcomes the dynamic load generated by the drive when the chain and sprocket mesh. Compared with the chain elevator, it works more smoothly and lighter, and can Faster running speed achieves higher productivity. Under the same production conditions, the tape can reduce the line load of the material and the line load of the traction components due to its high working speed and light weight, thus reducing the size of the entire machine. Self-respect. The use of high-strength steel wire rope core tape greatly improves the lifting height and conveying capacity of the elevator. The driving part is equipped with a slow-speed maintenance motor and is equipped with a backstop. The middle part adopts a double-channel structure, and the lower part adopts automatic tensioning. It is equipped with a specially structured tail roller to ensure automatic centering of the tape. The whole machine is equipped with safety protection devices such as deviation alarm, speed detection, and material level alarm to realize automatic monitoring of the status of the equipment during operation.

*

*