Product

CIEIEC

-

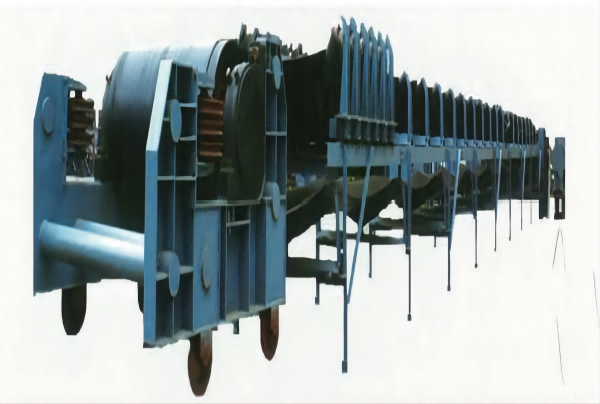

DX steel rope core belt conveyor

DX steel rope core belt conveyor

(1) DX type steel rope core belt conveyor is a universal series design and belongs to high strength belt conveyor.

The conveyor is suitable for large-volume and long-distance transportation of bulk materials.

(2) This series has seven types of bandwidth, five types of belt speeds and ten types of belt strengths. The composition of the conveyor

See table below.

(3) Can transport materials with loose density β=0.8-2.5t/m3

(4) The working environment temperature is generally 20-40℃. In cold areas, the driving part should

There is heating.

(5) The conveying distance is long, and the length of a single machine can reach several kilometers; the conveying capacity is large and the conveying volume is

Q=400-9600m3/h

(6) The elongation of the conveyor belt is small, about 1/5 of that of ordinary belts. The service life is 2-3 times longer than ordinary belts.

(7) It can be used in open-air situations, but if possible, use belt conveyor corridors or add protection.

cover.

(8) It can be transported horizontally, upwardly inclined and downwardly inclined.

For the explosion-proof type (underground or in the factory), generally it can only be satisfied with horizontal transportation or transportation with a small inclination angle. The so-called smaller inclination angle refers to the inclination angle that does not generate power generation during the downward movement and does not reverse after the upward movement stops.

View Details + -

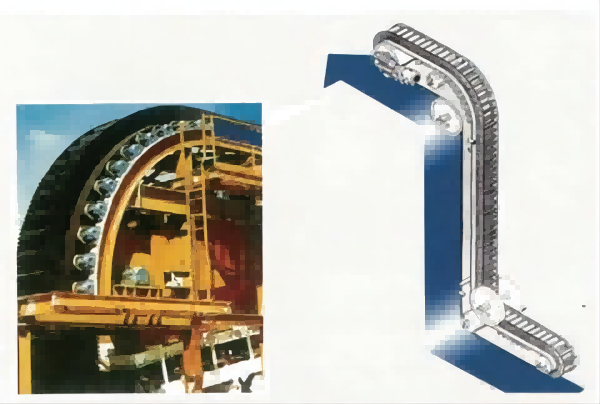

DJA/DJ High Angle Edge Guard Belt Conveyor

This series of corrugated side belt conveyors has the advantages of a general belt conveyor such as simple structure, reliable operation, and convenient maintenance. It also has the characteristics of large inclination angle transportation, compact structure, and small footprint. Therefore, it is suitable for large inclination angle transportation and vertical lifting of materials. ideal equipment. In addition, our company combines many years of design and production experience to solve the problem of easy deviation and large wear of the tape during the return journey. We designed a double return lower support and obtained a patent. Its advantage is to ensure the smooth operation of the return tape and extend the extended service life.

View Details +

DJA/DJ High Angle Edge Guard Belt Conveyor

This series of corrugated side belt conveyors has the advantages of a general belt conveyor such as simple structure, reliable operation, and convenient maintenance. It also has the characteristics of large inclination angle transportation, compact structure, and small footprint. Therefore, it is suitable for large inclination angle transportation and vertical lifting of materials. ideal equipment. In addition, our company combines many years of design and production experience to solve the problem of easy deviation and large wear of the tape during the return journey. We designed a double return lower support and obtained a patent. Its advantage is to ensure the smooth operation of the return tape and extend the extended service life.

View Details +

-

HQ/DY Moveable Belt Conveyor

The HQ\DY type mobile conveyor has a reasonable structure and is easy to move. It uses a winch device and can adjust the lifting height within a specified range. It is used for loading, unloading and transporting soil, sand, coal, gravel, grain, etc. in bulk or in pieces. materials. Widely used in construction sites, mines, coal, grain, freight yards, warehouses and other departments.

View Details +

HQ/DY Moveable Belt Conveyor

The HQ\DY type mobile conveyor has a reasonable structure and is easy to move. It uses a winch device and can adjust the lifting height within a specified range. It is used for loading, unloading and transporting soil, sand, coal, gravel, grain, etc. in bulk or in pieces. materials. Widely used in construction sites, mines, coal, grain, freight yards, warehouses and other departments.

View Details +

-

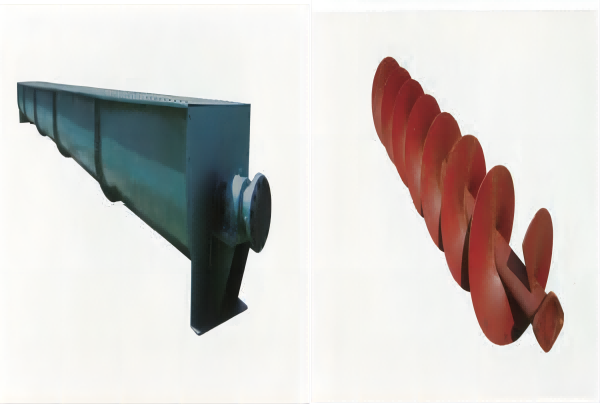

LSLINGX Screw Conveyor

LSⅡ\GX screw conveyor is mainly used to transport powdery, granular and small block materials, such as pulverized coal, furnace ash, cement, fertilizer, soda ash, sugar, grain, etc. The operating environment is -20℃+50℃; the material temperature is less than 20℃ and is transported horizontally or tilted <20°. It has a novel structure and good sealing performance. It can carry out intermediate loading and multi-point unloading at several positions. It is safe, convenient and reliable to operate. It is a conveying equipment widely used in chemical industry, building materials, food and other departments.

View Details +

LSLINGX Screw Conveyor

LSⅡ\GX screw conveyor is mainly used to transport powdery, granular and small block materials, such as pulverized coal, furnace ash, cement, fertilizer, soda ash, sugar, grain, etc. The operating environment is -20℃+50℃; the material temperature is less than 20℃ and is transported horizontally or tilted <20°. It has a novel structure and good sealing performance. It can carry out intermediate loading and multi-point unloading at several positions. It is safe, convenient and reliable to operate. It is a conveying equipment widely used in chemical industry, building materials, food and other departments.

View Details +

-

MS/MC/MZ Buried Scraper Conveyor

MS/MC/MZ Buried Scraper Conveyor

The buried scraper conveyor is a continuous conveying equipment that uses a moving scraper chain to transport bulk materials such as powder, small granules, and small blocks in a closed rectangular cross-section shell. Because the scraper chain is completely buried in the material when conveying materials, it is called "buried scraper conveyor".

The buried scraper conveyor has a simple structure, light weight, small size, good sealing, and is easy to install and maintain. It can not only transport horizontally, but also tilt and vertically; it can not only transport single machine, but also can be arranged in combination and transported in series; it can feed materials at multiple points and unload materials at multiple points, and the process layout is more flexible. Due to the closed shell, working conditions can be significantly improved when conveying materials and environmental pollution can be prevented. The model produced by our company is a general-purpose buried scraper conveyor, which can be widely used in chemical industry, metallurgy, light industry, grain, medicine, electric power and other departments.

View Details + -

XZ air Slide Conveyor

The XZ type air conveying chute uses a high-pressure centrifugal fan as the power source to keep the materials in the closed conveying chute fluidized and flow slowly toward the downward-sloping end. It is suitable for conveying powdery materials that are easy to fluidize such as cement. The main part of this machine has no transmission parts, making it easy to operate and manage. The equipment is light in weight, has low power consumption, has a large conveying capacity, and is easy to change the conveying direction. The tank is sealed throughout and adopts a rain-proof design. There is no exposure of materials during the entire conveying process and no pollution. Small, environmentally friendly advantages. Because the material-carrying parts are made of polyester breathable fabric, it is not suitable to use materials with large particle size, high moisture, and poor fluidization performance.

View Details +

XZ air Slide Conveyor

The XZ type air conveying chute uses a high-pressure centrifugal fan as the power source to keep the materials in the closed conveying chute fluidized and flow slowly toward the downward-sloping end. It is suitable for conveying powdery materials that are easy to fluidize such as cement. The main part of this machine has no transmission parts, making it easy to operate and manage. The equipment is light in weight, has low power consumption, has a large conveying capacity, and is easy to change the conveying direction. The tank is sealed throughout and adopts a rain-proof design. There is no exposure of materials during the entire conveying process and no pollution. Small, environmentally friendly advantages. Because the material-carrying parts are made of polyester breathable fabric, it is not suitable to use materials with large particle size, high moisture, and poor fluidization performance.

View Details +

-

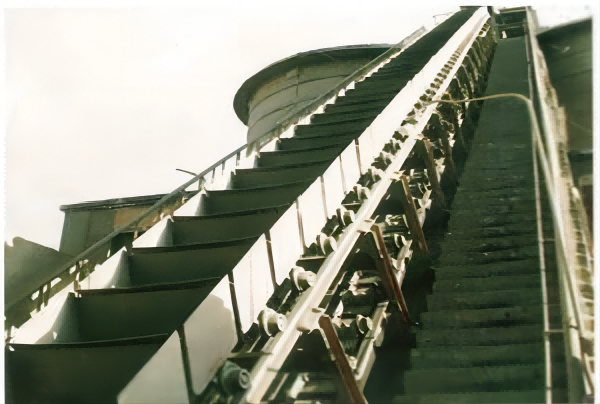

DTIINDTII Fixed Belt Conveyor

DTIINDTII Fixed Belt Conveyor

DTII\DTII(A) type fixed belt conveyor is a universal series of products designed uniformly in China. Its main parameters and performance are in line with ISO international standards. It is widely used in metallurgy, mining, coal, ports, electric power, building materials, Chemical, petroleum and other industries. A single machine or multiple units form a transportation system to transport materials, which can transport various bulk materials and finished items with a density of 500-2500kg/m³.

This series of conveyors can meet the requirements of horizontal and inclined conveying, and can also adopt a conveying form with a combination of convex arc, concave arc sections and straight sections. The material lumpiness allowed by the conveyor depends on the bandwidth, belt speed, groove angle and inclination angle. The maximum block size applicable to various bandwidths is recommended for this series according to Table 1.

View Details + -

TD75 Universal Fixed Belt Oonveyor

TD75 Universal Fixed Belt Oonveyor

TD75 universal fixed belt conveyor (called TD75 type) is widely used in metallurgy, coal, transportation, building materials, mining, chemical industry, and ports due to its advantages of large transportation capacity, simple structure, easy maintenance, low cost, and strong versatility. and other departments, used to transport bulk materials or finished items. It can be arranged horizontally or tilted according to process requirements.

The temperature of the materials transported by the TD75 belt conveyor is below 50℃. Environment temperature +40℃-25℃. If corresponding protective measures are taken, it can also be applied to occasions with special requirements such as explosion-proof, waterproof, anti-corrosion, heat resistance, and cold resistance.

View Details + -

QBG Link Plate Conveyorl

QBG Link Plate Conveyorl

QBG chain plate conveyor is an auxiliary equipment for transportation machinery. It is suitable for conveying small pieces of materials with small specific gravity over short distances in a certain amount. Its feeding particle size is below 350mm. The material temperature should not be higher than 350℃.

This machine is widely used in mining, chemical industry, electric power, building materials, metallurgy, petroleum, light industry and other industrial sectors to transport ore and other materials from storage bins to transportation machinery or other equipment. The machine can be installed horizontally or tilted, and its maximum inclination angle shall not exceed 25°.

View Details + -

SCD Deep-Pan Conveyor

The SCD deep pan trough conveyor is a new type of equipment newly developed by our company for clinker transportation. Based on many years of production of clinker bucket conveyors and pan trough conveyors, our company absorbed German technology and developed a deep pan trough conveyor. It has large conveying capacity, strong climbing ability, long service life of the traction parts, stable operation, and can Use under working conditions not exceeding 350℃.

View Details +

SCD Deep-Pan Conveyor

The SCD deep pan trough conveyor is a new type of equipment newly developed by our company for clinker transportation. Based on many years of production of clinker bucket conveyors and pan trough conveyors, our company absorbed German technology and developed a deep pan trough conveyor. It has large conveying capacity, strong climbing ability, long service life of the traction parts, stable operation, and can Use under working conditions not exceeding 350℃.

View Details +

-

DSISDBF clinker chain bucket conveyor

DSISDBF clinker chain bucket conveyor

The DS type continuous chain bucket conveyor is a self-improved design based on the absorption and digestion of advanced technology from West Germany. It is suitable for horizontal or inclined (inclination angle ≤ 60°) transportation of various powdery and block bulk materials, such as cement. Clinker, iron slag, ore sand, limestone, coke, etc. The heat resistance and reliability are better than those of plate conveyors, belt conveyors and vibrating conveyors. The longest single conveyor can reach about 150m, and it saves more than 50% of energy than plate conveyors. Widely used in building materials, metallurgy, coal, chemical industry, electric power and other industrial sectors.

The SDBF continuous chain bucket conveyor can be arranged horizontally or inclined (≤ 60°) and is designed in accordance with the international standard ISO2140-1975. The advantage of this machine is that it is suitable for conveying high-temperature materials (material temperature ≤ 600°C) and long-distance conveying bulk density ≤ 2t/m3. Mainly used in the cement industry to transport clinker. In the chemical, aluminum-magnesium, metallurgy, electric power and other industries, it is also widely used to transport high-temperature and grinding materials.

View Details + -

FU Chain Conveyors

The FU type chain conveyor is a machine that is installed in a closed rectangular cross-section body and uses a moving scraper chain to continuously transport powdery, granular and small bulk materials horizontally or at a small angle (<15°). Product, this product has low energy consumption, high efficiency, good sealing, low pollution, high operational reliability, low failure rate, low noise, low wear, long service life, simple structure, flexible process layout, and can add materials at multiple points and multi-point unloading and other advantages. It is suitable for building materials, chemical industry, food, mining, thermal power, metallurgy, port and other industries.

View Details +

FU Chain Conveyors

The FU type chain conveyor is a machine that is installed in a closed rectangular cross-section body and uses a moving scraper chain to continuously transport powdery, granular and small bulk materials horizontally or at a small angle (<15°). Product, this product has low energy consumption, high efficiency, good sealing, low pollution, high operational reliability, low failure rate, low noise, low wear, long service life, simple structure, flexible process layout, and can add materials at multiple points and multi-point unloading and other advantages. It is suitable for building materials, chemical industry, food, mining, thermal power, metallurgy, port and other industries.

View Details +